Motorcycle Parts New Zealand Specialists Fundamentals Explained

Table of ContentsThe Buzz on Motorcycle Parts New Zealand SpecialistsThe smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is DiscussingFacts About Motorcycle Parts New Zealand Specialists RevealedHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.The Best Strategy To Use For Motorcycle Parts New Zealand SpecialistsThe 6-Minute Rule for Motorcycle Parts New Zealand SpecialistsLittle Known Facts About Motorcycle Parts New Zealand Specialists.Some Known Details About Motorcycle Parts New Zealand Specialists

Get to out to one of our experts today.CNC machining technology is swiftly becoming the focal factor of several different production procedures around the globe as a direct result of its lots of advantages over various other techniques. Additionally, the markets that make motorbikes have jumped on board with this trend. The most ingenious companies are currently developing their engine elements and wheels utilizing machining strategies initially developed for motorcycle parts.

On the various other hand, the impacts of sector are the primary emphasis of this short article. Let's get straight right into it. You might be questioning why we make use of. It is not hard to fathom the factors that resulted in this outcome. Since we have your focus let us clarify the rationale behind this modern-day advancement in the motorcycle production market.

Some Ideas on Motorcycle Parts New Zealand Specialists You Should Know

In enhancement, you have total control over the appearance of the elements, even down to the min information. Occasionally, motorcyclists may decide to spruce up their experience by mounting aftermarket parts or customizing the bike's transformation.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking About

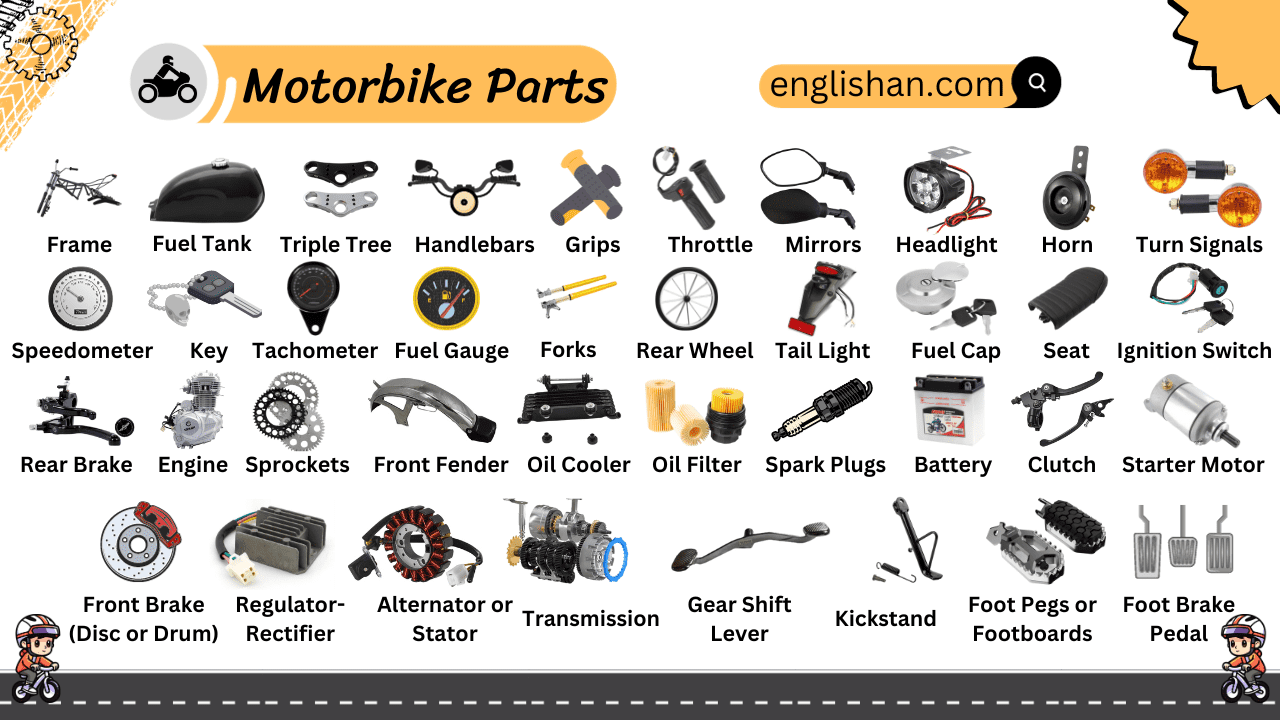

CNC machining might be made use of to make nearly all of a bike's steel and plastic elements. To proceed, we'll review numerous machined components for bikes. In comparison to those on cars and trucks, wheels on motorbikes tend to be much more apparent. Consequently, the bike's appearances may be enhanced with the suitable customization of these wheels.

When personalizing the wheels, the disks are where the emphasis ought to be. The bulk of them are made out of aluminum. Light weight aluminum alloys are popular for the superior machining capabilities that they have. Milling treatments are made use of to obtain the desired degree of wheel modification. An additional facet of the motorbike that might be individualized is the tires.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

When it comes to a lorry (or a motorcycle), one of the most vital part is the engine. A number of individuals allude to it as the "heart" of the automobile. On the other hand, the camshaft, the cylinder head, and the pistons tend to be complex and need layouts with a high degree of accuracy.

Lighting is one more facility element of customization. Usage just premium things, however, since these lights are vital for the safety of motorcyclists and other chauffeurs or individuals on the road, particularly during the night. Motorbike headlights have three almosts all: the light bulb, or light source, the lens, and the housing. Specifically, we customize the lens and the housing.

Milling processes with a flawless surface would certainly cause the lenses having a reflective top quality that resembles that of a mirror. The cover, on the various other hand, is not made up of breakable materials; instead, it is created out of difficult polymers that can be machined right into even more detailed patterns.

Motorcycle Parts New Zealand Specialists - The Facts

They frequently have sophisticated geometries with a wide range of minute information. Bike producers frequently cast these parts, however only for the manufacturing of bespoke parts. Nevertheless, CNC machining is the approach of option when producing unique items. Machining on 5 axes in today's world is the ways whereby any kind of style form might be realized.

Pick Runsom for your customized bike parts! We have the capability to make challenging and trendy components making your motorcycle matchless.

Right here are a couple of examples of steels typically utilized in motorcycle part this article machining. Light weight aluminum is the main product utilized by business specializing in generating custom-made bike components to produce many of these components - Motorcycle Parts New Zealand Specialists.

Zinc describes an additional metal that is really light in weight and has terrific go to these guys machining high qualities due to its high mechanical strength. This product may be developed into almost any type of shape and keeps its dimensions well. Also mission-critical elements that require a high degree of accuracy might take advantage of their usage.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

One more steel that sees heavy usage in the production of CNC-customized elements is magnesium. It is among the lightest steels that are currently obtainable and has excellent machinability attributes and toughness proportionate with its reduced weight. One of the disadvantages of magnesium is that its dust might easily ignite.

As a result of its remarkable machinability and weldability, stainless-steel is an alloy that is especially fit for CNC processes. They have fantastic corrosion resistance and a high aesthetic appeal. Their most common usage in creating various motorcycle components is fasteners, such as screws and bolts. Their reduced susceptibility to oxidation and corrosion makes them ideal for this usage.

The 25-Second Trick For Motorcycle Parts New Zealand Specialists

It appears that CNC turning and crushing are the foundational processes. Nevertheless, alternative techniques exist, such as exploration. Allow's investigate much of these machining techniques detailed. The CNC turning method is considered a subtractive production technique. Additionally, it needs maintaining bars of material, usually plastic or use this link steel, ready and afterwards turning a reducing device to get rid of sections of the material as the material is transformed.

These methods are just as essential and generate parts with high precision and constant high quality. They are specifically: grinding, laser cutting, and exploration. The term "surface area finish" describes post-processes after the first machining phase. Motorcycle Parts New Zealand Specialists. The procedures help enhance the general high quality of the machined motorbike components. Below are the short intro, pros and disadvantages of five surface therapy methods.

The Definitive Guide to Motorcycle Parts New Zealand Specialists